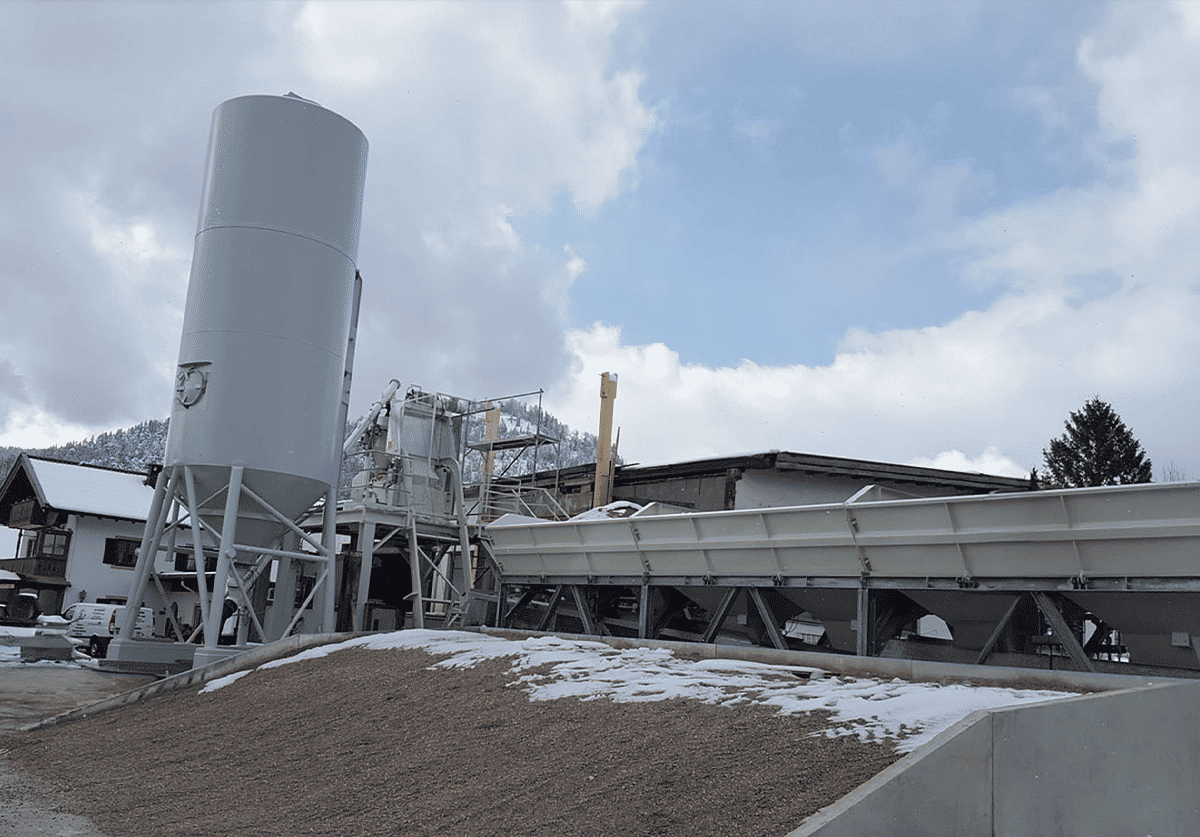

Ammann ABC Supertech Batch Asphalt-Mixing Plant

ammann

The Ammann ABC Supertech Batch Asphalt-Mixing Plant delivers exceptional performance for large-scale paving projects. With a production capacity of 160 TPH and an advanced RAC recycling system, it supports sustainable operations while reducing waste. Its innovative dryer drum technology (T-2080 / MIBGS-1.12) ensures efficient asphalt heating, and the high-performance filter and screening system—featuring a 327 m² filter surface and VA 1536 [4-5] screen—guarantees uniform mix quality. The plant’s robust hot mineral silo capacity of 16 tons enables seamless production flow and consistent mix properties. Designed for highways, urban roads, and industrial applications, its modular design facilitates easy maintenance and rapid setup at diverse construction sites. This state-of-the-art facility exemplifies efficiency, durability, and environmental compliance in every aspect. Engineered for reliability and peak performance, it is the ideal solution for modern infrastructure challenges.

Ammann ABC Supertech Batch Asphalt-Mixing Plant

ammann

The Ammann ABC Supertech Batch Asphalt-Mixing Plant delivers exceptional performance for large-scale paving projects. With a production capacity of 160 TPH and an advanced RAC recycling system, it supports sustainable operations while reducing waste. Its innovative dryer drum technology (T-2080 / MIBGS-1.12) ensures efficient asphalt heating, and the high-performance filter and screening system—featuring a 327 m² filter surface and VA 1536 [4-5] screen—guarantees uniform mix quality. The plant’s robust hot mineral silo capacity of 16 tons enables seamless production flow and consistent mix properties. Designed for highways, urban roads, and industrial applications, its modular design facilitates easy maintenance and rapid setup at diverse construction sites. This state-of-the-art facility exemplifies efficiency, durability, and environmental compliance in every aspect. Engineered for reliability and peak performance, it is the ideal solution for modern infrastructure challenges.

Ammann ABC Supertech Batch Asphalt-Mixing Plant specs & features

Product Description

The Ammann ABC Supertech Batch Asphalt-Mixing Plant delivers exceptional performance for large-scale...

Ammann ABC Supertech Batch Asphalt-Mixing Plant Comparison with Similar Asphalt Batching Plant

Ammann ABC Supertech Batch Asphalt-Mixing Plant

Plant Type

160

Max Production Capacity

160TPH

Dryer Drum Diameter

1.8m

Dryer Drum Length

7 mm

Burner Capacity

12MW

Fuel Type

Light or heavy oil

Hot Mix Storage Silo Capacity

16T

Batch Size

-

Cycle Time

-

Cold Feed Bins (no. Of Bins)

-

Nilang ABP 80 Asphalt Batch Mix Plant

Plant Type

Stationary

Max Production Capacity

100TPH

Dryer Drum Diameter

1.5m

Dryer Drum Length

6m

Burner Capacity

8MW

Fuel Type

Diesel / LDO / Furnace Oil

Hot Mix Storage Silo Capacity

15T

Batch Size

1000kg

Cycle Time

45seconds

Cold Feed Bins (no. Of Bins)

4 / 25

Apollo WetMix 100–250 Asphalt-Mixing Plant

Plant Type

-

Max Production Capacity

-

Dryer Drum Diameter

-

Dryer Drum Length

-

Burner Capacity

-

Fuel Type

-

Hot Mix Storage Silo Capacity

-

Batch Size

-

Cycle Time

-

Cold Feed Bins (no. Of Bins)

-

Ammann ABM Easybatch 90 Asphalt-Mixing Plant

Plant Type

90

Max Production Capacity

90TPH

Dryer Drum Diameter

4.48m

Dryer Drum Length

4.48m

Burner Capacity

6.5MW

Fuel Type

Natural gas, fuel oil extra light, heavy oil

Hot Mix Storage Silo Capacity

10T

Batch Size

1088kg

Cycle Time

288000seconds

Cold Feed Bins (no. Of Bins)

Parker StarMix 180 Asphalt Batching Plant

Plant Type

-

Max Production Capacity

180TPH

Dryer Drum Diameter

2.2m

Dryer Drum Length

8.0m

Burner Capacity

-

Fuel Type

-

Hot Mix Storage Silo Capacity

40T

Batch Size

2250kg

Cycle Time

-

Cold Feed Bins (no. Of Bins)

-

Compare Asphalt Batching Plant

Ammann ABC Supertech Batch Asphalt-Mixing Plant

Nilang ABP 80 Asphalt Batch Mix Plant

Add any equipment

to compare

Get instant quotation on whatsapp

Connect with Seller Instantly

Related Products

More Products from Ammann